References

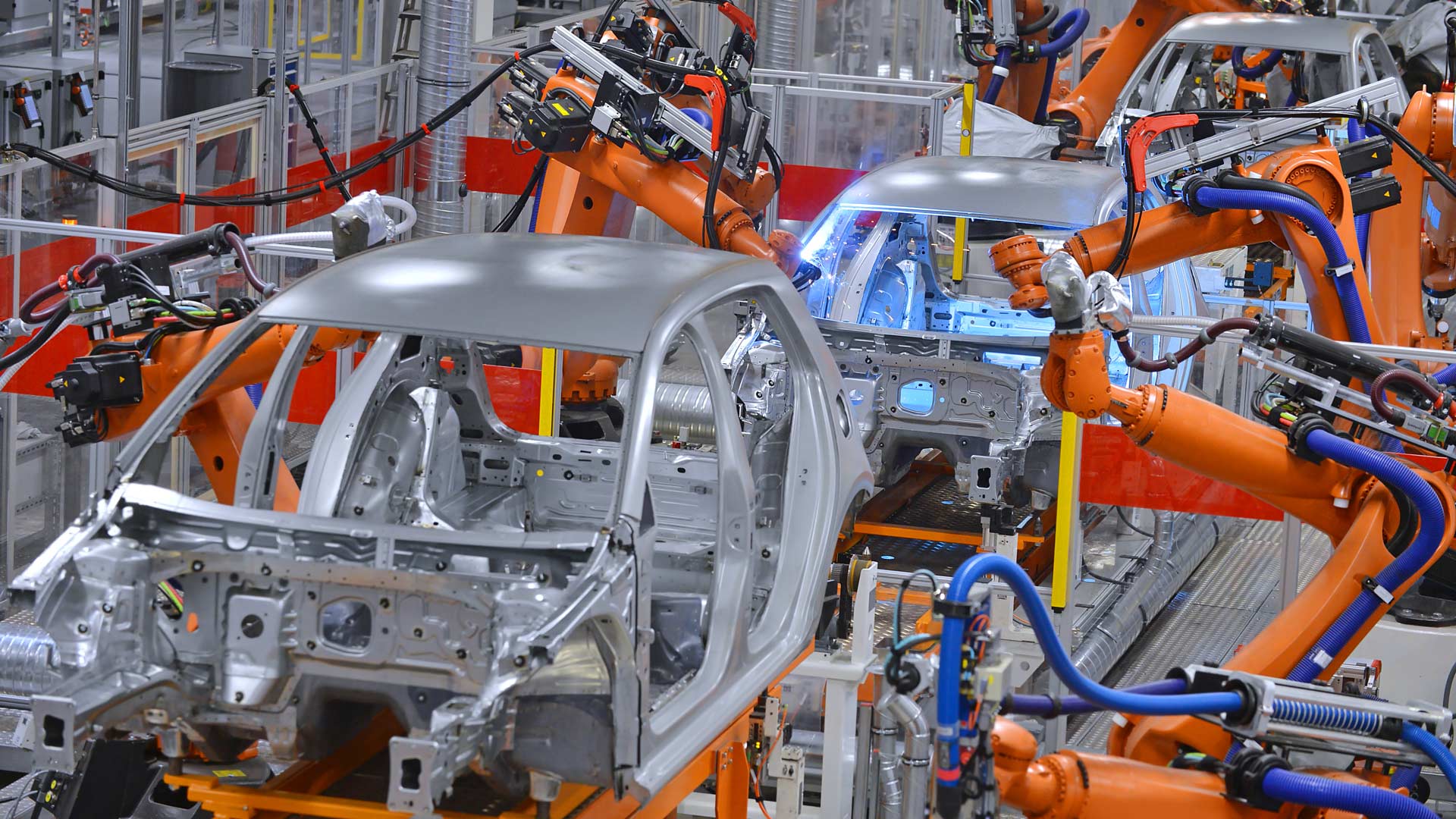

Diverse industries,

one objective: satisfied customers!

Our aim is to have satisfied customers. We are a reliable partner to many industries and have created a wide range of industrial solutions for our customers during our 120-year company history. Thanks to our many years of experience and expertise, we have succeeded in achieving precisely this objective.

This aim of achieving a high level of satisfaction among our customers is the biggest challenge we face every day, but also the reason for our success! We have developed and implemented many optimizations, integrations and automations for complex infrastructures and production processes. As this selection of our many different references shows, we have a wealth of experience behind us. Find out for yourself and reap all the benefits!